Minitron - Coil-Winding Feeder

Wire - Constant Tension Feeding Device

Advanced High Tech Solutions for Coil and Motor Winding Process Control

MINITRON is one of the latest results from BTSR INTERNATIONAL, a worldwide leading company in the design of high tech solutions and innovation development in a wide variety of industrial sectors.

MINITRON the Ultimate in Wire Constant Tension Feeding

MINITRON represents a revolutionary new generation Wire Constant Tension Feeding device, unique in terms of functionality and performance, capable of adjusting with utmost accuracy the tension of the wired in motor and coil winding processes.

An innovative Solution based on the BTSR Dual-Drive Feeding System, Tension Profiler Function and Double Loop Control System bringing new and unique measurable benefits in terms of TOP Quality Control and Production Efficiency in coil winding process.

An innovative Solution based on the BTSR Dual-Drive Feeding System, Tension Profiler Function and Double Loop Control System bringing new and unique measurable benefits in terms of TOP Quality Control and Production Efficiency in coil winding processes.

Minitron - Coil-Winding Feeder Specs

MAIN BENEFITS

- TOP Quality Standards Goal

is ensured by the highest coil winding quality and repeatability, thanks to BTSR ‘Double Closed Loop’ Technology guaranteeing the most accurate and precise wire tension control.

- TOP Versatility

is guaranteed by Fully programmable parameters according to the wire requirements and possibility to dynamically modify the wire control tension according to the operating stage (‘Tension Profiler’ Function).

- TOP Process Production Efficiency

Thanks to the user-friendly programming options and easy and quick machine setup.

- TOP Productivity

is guaranteed by the capability to work at the maximum possible process speed.

- Minimized Labour Costs

is possible thanks to the user-friendly programming options.

- A wide application range

is possible thanks to the wide wire tension and diameter range of MINITRON

- Centralized programming and monitoring

is possible thanks to MATRIX TOUCH COIL controller which will allow to program and control MINITRON units and monitoring the whole process production status also in graphical form.

Features

- Advanced Digital Display for real-time operational information reading.

- Ergonomic Keys for easy operation and synchronized alarm signaling

- Automatic Compensation Arm for wire 'Storage and Release'

- Dual Drive Feeding System for controlling and maintaining a constant winding feeding tension

- Wire pretensioner cleaner and high accuracy tension sensor load cell

- MATRIX TOUCH COIL allows to memorize, load, visualize and control even in graphic way the wire tension, speed and wire consumption (LWA)

Technical Features

- Display tension range 0 grams – 5.000 g (cN)

- Programmable tension range 50 g ÷ 4.000 g (cN) with resolution 10 gram

- Wire diameter 0,08 ÷ 1,5 mm - 40 ÷ 14,5 AWG

- Wire diameter range From. From. 0,08 Up to 1.038 mm 40 up to 18 AWG

- Feeding speed range 0 ÷ 12,5 m/s - 0 ÷ 750 mt/min

- LWA function: exact wire consumption measuring (Length Wire Absorption) with resolution of 2 mm.

- AUTO-LWA and alarm range setting Tension LWA ± 1 % upto ± 25 % Meter LWA ± 0,1 mt up to 20 mt

- OEM machine computer interface Standard : RS485, Canbus Optional : Profinet, Ethernet IP, Ethercat Other on demand

- Power supply voltage 48VDC ± 10%

- Overall Dimensions (mm) 600 L x 126 W x 170 h

- Weight: 10.2kg

- Minimum Air Pressure 4 bar

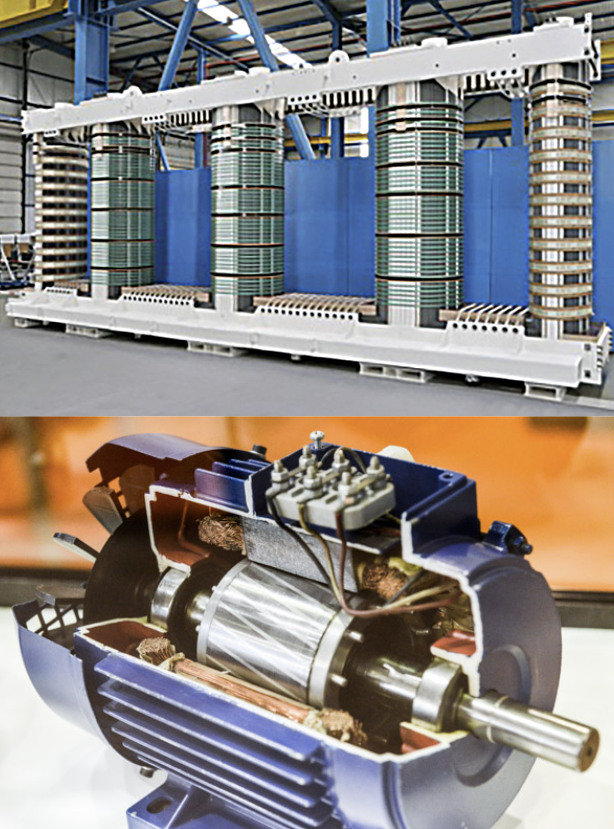

APPLICATIONS

Main Application Processes

- Single flyer winding (STATOR MOTORS)

- Needle Winding (BRUSHLESS MOTORS)

- Double Flyer (ARMATURE MOTORS)

Main Manufacturing Sectors

- Automotive

- Power tools

- Transformer industry

- Electric bicycle

DOUBLE CLOSED CONTROL LOOP (BTSR Patent)

MOTOR TORQUE (BTSR Patent)

1st closed loop

Total Input Controls

Operated by the motor control force (Torque). Detects and adjust any input wire tension variation caused by:

• Input tension variation (full/empty feeding bobbin)

• Input wire entanglement

LWA Length of Wire Absorbed (BTSR Patent)

2nd closed loop

Total Output Controls Operated by means of multiple motor controls, Speed/Wire consumption.

Detects and monitor:

• Any dimensional variation of coil formers.

• A wrong wire dimension (diameter/AWG).

• Accumulation of dirtiness inside the wire guide

• Damage of the wire guide.

• Any mechanical variation or friction on the contact points after the tension feeder device (Minitron - Megatron - Gigatron).

• Wire passing through the wire guides with different angles and frictions (wrong thread-up).

CONSTANT TENSION VALUE GUARANTEED

Output Wire Tension (LIGHT BLUE color) is kept constant at the set value, despite of input wire feeding tension variations (RED color) and/or wire speed variations (GREEN color) during the working process.

MATRIX TOUCH COIL TERMINAL

Centralized programming and monitoring is possible thanks to MATRIX TOUCH COIL controller which will allow you to program and control MINITRON - MEGATRON - GIGATRON units and monitoring the whole process production status also in graphical form.

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

NAICS Codes:334515, 54138, 811219,811310

Cage Code: 4P2J9

Duns Number: 79-119-1351

Upcoming Events

Contact Info:

MOTOR DIAGNOSTIC SYSTEMS, INC.

inside.sales@mdsusa.net

Sales: +1 (970) 461-1348

or +1(877) 461-1348

Fax: +1 (866) 223-0800

Business Hours

- Mon - Fri

- -

- Sat - Sun

- Closed

All Rights Reserved | Motor Diagnostic Systems Powered by The Way Consulting